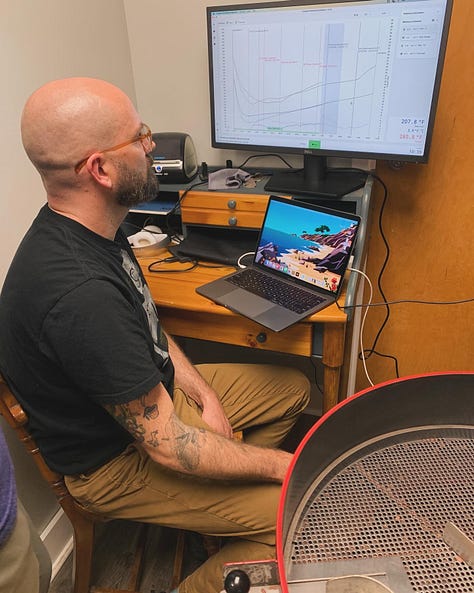

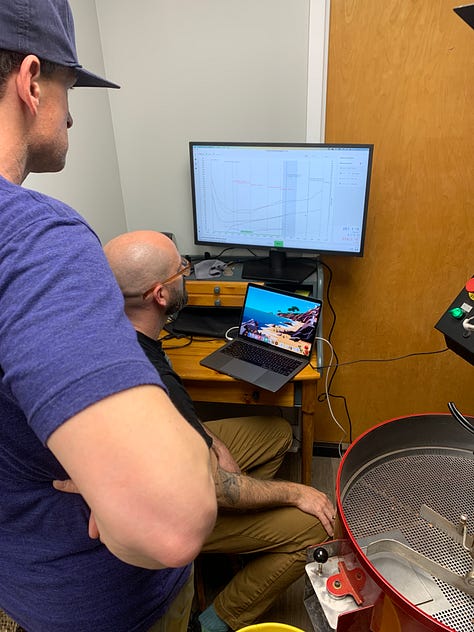

how to connect a Behmor roaster with Artisan software to track your roasts

a small batch profile roasting breakthrough! roasting (and the chocolate we make with it) just got better

A really exciting breakthrough for makers roasting using the Behmor roaster! Whether you are using a Behmor for production, or for test-batch roasting.

The background

Nicole of The Chocolate Passport a…